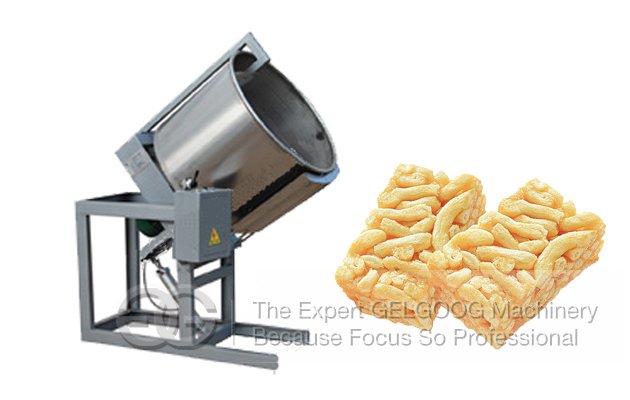

Continuous Caramel Treats/Sachima Production Line

| MOQ: | 1 Set/Sets |

|---|---|

| Brand: | GELGOOG MACHINERY |

| Certification: | CE |

| Supply Ability: | 100 Sets/Month |

| PAY METHOD: | WEST UNION L/C T/T CASH |

| Warranty Time: | 12 Months |

| LOADING PORT: | Qingdao Port |

| Country Of Origin: | China |

Application

It is used to make sachima/caramel, peanut brittle etc.

Main Feature

stainless steel,simple, easy to operate, high quality, continuous working.

Features

Introduction:

Continuous Caramel Treats/Sachima Production Line consists of three parts, mixer, press and mold machine, cutting machine. Machines are made of stainless steel, can be used to make caramel treats/sachima, peanut/sesame brittle, nuts cakes etc. Mixer machine uses automatic heat, heat is more uniform; pneumatic lifting device, discharge material more convenient; PP sheet scraping with non-stick feature, easy to fall off, low noise etc. After mixing material and syrup well, put all material into tray, flatten material, make them put into tray uniform, them put tray on molding machine, press material. Last step, conveying tray with material to cutting machine. Cutting machine cutter is customized according to customers cutting size demand, and tray groove is corresponding with cutter. Cutting machine is L type, making vertical cutting and cross cutting, get square shape sachima. Before using machine, check all machines well, then connect power, test, when machine stable, can start work. During production, pay attention to material mixing and putting into tray, ensure mixing well and put into tray flatten, otherwise will influence products taste and moudling effect.

Continuous Caramel Treats/Sachima Production Line consists of three parts, mixer, press and mold machine, cutting machine. Machines are made of stainless steel, can be used to make caramel treats/sachima, peanut/sesame brittle, nuts cakes etc. Mixer machine uses automatic heat, heat is more uniform; pneumatic lifting device, discharge material more convenient; PP sheet scraping with non-stick feature, easy to fall off, low noise etc. After mixing material and syrup well, put all material into tray, flatten material, make them put into tray uniform, them put tray on molding machine, press material. Last step, conveying tray with material to cutting machine. Cutting machine cutter is customized according to customers cutting size demand, and tray groove is corresponding with cutter. Cutting machine is L type, making vertical cutting and cross cutting, get square shape sachima. Before using machine, check all machines well, then connect power, test, when machine stable, can start work. During production, pay attention to material mixing and putting into tray, ensure mixing well and put into tray flatten, otherwise will influence products taste and moudling effect.

Advantage:

1.Working process is simple, only consist of mixing machine, molding and cutting machine. Of course if need other machine, like sugar pot, pillow packing machine, we can supply.

2.Mixing machine is nonstick barrel wall, stir uniform, non-stick pot

3.High quality, machine is made of stainless steel 304, conform food safety requirement.

4.Sachima size can be adjustable. Our machine can customize tray groove and cutter distance to control product size.

5.Machines working is automatic. Between molding machine and cutting machine, there will be conveyor, making processing more easier, easy to operate.

6.Automatic control reciprocation, flattened uniformly smooth.

7.Automatic dicer, one time molding, product size, weight keep same.

8.Elegant and beautiful performance.

9.Compact structure and durable.

Technical Data

| Name | Model | Capacity | Working Pressure | Barrels Diameter | Dimension | Weight |

|

Sachima Nonstick Mix Sugar Machine |

GGM-600 | 15KG/H | 0.3-0.5Mpa | 600mm | 1200*600*1800 | 300KG |

| GGM-760 | 20KG/H | 0.3-0.5Mpa | 760mm | 1200*800*1960 | 360KG | |

| Name | Model | Volt | Working Range | Capacity | Dimension | Weight |

| Sachima Molding and Cutting Machine | GG-760 | 380V | 15*15*60mm | 300-500 kg/h | 2000*1400*2500mm | 1000kg |

| GG-960 | 380V | 15*15*60mm | 500-800 kg/h | 2300*2000*2500mm | 1200kg |

FAQ

1. What's the capacity of this Sachima Production Line?

We have 15kg/h and 20kg/h for your selection. Also we can customize different capacity for our clients.

2.How can we get a best price?

We have 15kg/h and 20kg/h for your selection. Also we can customize different capacity for our clients.

2.How can we get a best price?

Quality is the heart of one company. We can not promise the lowest price, but we can promise the best quality and most reasonable price. On the other hand,bigger order you placed, cheaper price you will get!

3.Where is your factory located? How can I visit there?

Our factory is located in Zhengzhou, Henan Province, China. You can fly to Xinzheng Airport directly. We will pick you up on Xinzheng International airport.

4.How about your after-sale service?

Any question you have,no matter whether in warranty period or not. As long as you give me a email or video. Our engineers and I are very willing to solve the problem for you. We not only have high quality machine, but also we have very good after-sales service. So that is why we have many returned customers.

Related Products